Engineered for -30°C: The Security Camera for Harsh Winters

Normal Cameras Fail at -20°C? The SDL500 Is Engineered for Canadian Winters

There’s a scenario all too common for property owners and security installers in Canada: a heavy snowfall, temperatures plummeting to -25°C, and the security camera you rely on simply goes dark. The screen shows “Offline.” This isn’t just an inconvenience; it’s a critical failure that leaves assets vulnerable when they are most isolated. For businesses, this means unprotected construction sites or remote infrastructure. For homeowners, it means a complete loss of situational awareness.

As an engineer with over 13 years of hands-on experience designing solar security cameras, I’ve seen this exact failure countless times. The market is flooded with cameras that claim to be “outdoor-rated,” but they crumble under the genuine stress of a harsh Canadian winter. The core issue is that their design and components are simply not specified for sustained, sub-zero operation. They are built for a price point, not for performance in extreme environments.

This widespread problem creates a significant opportunity for security professionals—distributors, installers, and brand owners. By understanding why these cameras fail and offering a genuinely robust solution, you can build a reputation for reliability and capture a market tired of seasonal product failures. Let’s break down the engineering reasons for these failures and explore how a purpose-built camera like our UBOXCAM SDL500 is specifically designed to thrive in the cold.

The Cold, Hard Truth: Why Standard Security Cameras Freeze Up

When a typical battery-powered camera stops working at -20°C, it’s not a random defect. It’s a predictable failure rooted in fundamental physics and cost-cutting compromises. From my perspective in the factory, these are the four primary points of failure we’ve engineered our products to overcome.

1. Battery Chemistry Failure

The number one culprit is the battery. Most consumer-grade solar cameras use standard Lithium-ion (Li-ion) 18650 cells because they are cheap and widely available. However, the electrolyte chemistry inside these batteries slows dramatically in freezing temperatures. Below 0°C, their ability to discharge power drops off a cliff. At -20°C, the internal resistance becomes so high that the battery simply cannot deliver the voltage required to power the camera’s motherboard, sensor, and Wi-Fi module, causing a shutdown. Furthermore, attempting to charge a frozen Li-ion battery can cause irreversible damage through a process called lithium plating, permanently reducing its capacity and lifespan.

2. Material Brittleness and Seal Failure

A camera’s IP (Ingress Protection) rating is only as good as its materials. Standard cameras often use ABS plastic for their housing and generic nitrile rubber for their seals. In extreme cold, these materials lose their flexibility and become brittle. The plastic can develop micro-cracks, and the rubber seals can harden and shrink, breaking the watertight barrier. This allows moisture to seep in, which then condenses on the cold electronics, causing short circuits and permanent damage. This is why a camera rated IP66 in a lab can fail after one winter season in the field.

3. Lens Fogging and Icing

Even if the camera stays on, its vision can be compromised. When the camera’s internal electronics generate a small amount of heat in a frigid environment, a temperature differential is created. This causes moisture trapped inside the housing to condense on the coldest surface—the inner side of the lens cover. The result is a foggy, useless image. In severe cold, this condensation can freeze, covering the lens in a layer of ice and rendering the camera completely blind.

4. Mechanical Seizure in PTZ Cameras

For Pan-Tilt-Zoom (PTZ) models, the cold presents a mechanical challenge. The lubricants used in the small motors and gears of standard PTZ cameras are not rated for low temperatures. As the temperature drops, this grease thickens, increasing friction. The motors must work harder to move, drawing more power from an already struggling battery. Eventually, the lubricant becomes so viscous that the motors seize entirely, leaving your camera stuck pointing in one direction.

Introducing the SDL500: A Masterclass in Cold-Weather Engineering

Understanding these failure points is the first step; engineering a solution is the next. The UBOXCAM SDL500 was not adapted for the cold; it was conceived for it. Leveraging our factory’s direct control over design and components, we built a camera specifically to provide year-round security in demanding climates like Canada, the northern US, and Scandinavia. It represents a fundamental shift from a consumer-grade to an industrial-grade mindset.

Core Feature Deep Dive: How the SDL500 Defeats the Cold

A side-by-side comparison starkly reveals the engineering chasm between a standard camera and a professionally-built one. For our B2B partners, these technical details translate directly into lower return rates, fewer service calls, and higher customer satisfaction.

| Feature | Standard Security Camera | UBOXCAM SDL500 Cold-Weather Solution |

|---|---|---|

| Battery Technology | Standard Li-ion 18650 cells | Automotive-Grade Low-Temperature LiFePO4 Battery Pack |

| Certified Operating Temp | -10°C to 50°C (Unreliable below 0°C) | -30°C to 60°C (Proven stable operation) |

| Battery Management (BMS) | Basic overcharge/discharge protection | Advanced BMS with Low-Temp Pre-heating & Charging Cutoff |

| Housing Material | Standard ABS Plastic | Industrial-Grade, UV-Resistant Polycarbonate/Metal Alloy |

| Waterproofing Seals | Single nitrile rubber gaskets | Silicone double-sealed gaskets with anti-freeze properties |

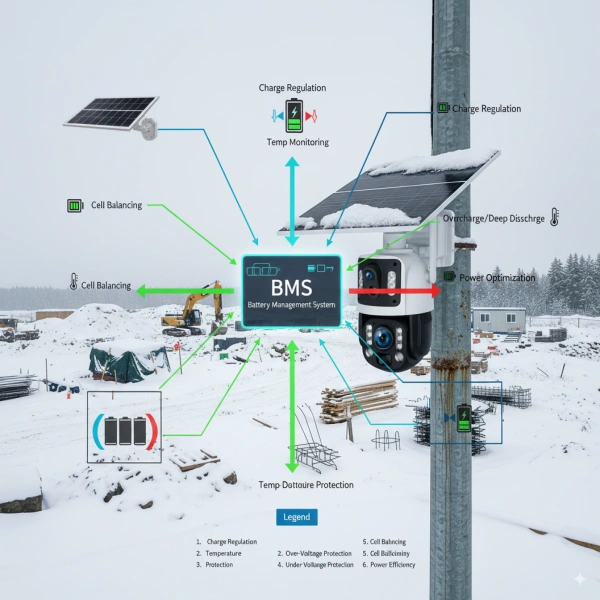

The Heart of Reliability: Our Advanced Battery Management System (BMS)

The single most critical component for cold-weather survival is the Battery Management System (BMS). Think of it as the battery’s brain. While a basic BMS only prevents catastrophic failure, an advanced BMS, like the one in our SDL500, actively manages battery health and performance in extreme temperatures. It’s a key piece of technology we’ve perfected over years of R&D. For a deeper dive, explore our analysis on BMS as a key technology for solar cameras.

Our proprietary BMS incorporates three crucial cold-weather functions:

- Low-Temperature Charging Cutoff: The BMS automatically prevents the solar panel from charging the battery if the battery’s internal temperature is below 0°C. This prevents the dangerous and damaging lithium plating effect, preserving the battery’s long-term health.

- Intelligent Pre-heating Circuit: Before initiating a charge cycle in freezing conditions, the BMS directs a small amount of power to a heating element within the battery pack. This gently warms the cells to a safe charging temperature (above 5°C), ensuring efficient charging and maximum power absorption from the winter sun.

- Temperature-Compensated SoC Algorithm: Our BMS uses an algorithm that accounts for temperature when calculating the State of Charge (SoC). This means the battery percentage you see in the app is accurate and reliable, even at -20°C, eliminating false readings that plague standard cameras.

Application Case Study: Securing a Canadian Construction Site in Winter

Theory and specs are important, but real-world performance is the ultimate test. This is where our B2B partners see the true value.

- Problem: A general contractor managing a large housing development in Calgary, Alberta, was losing tens of thousands of dollars to equipment and material theft during the winter months. Their existing wireless cameras, from a well-known brand, would consistently fail overnight as temperatures dropped below -20°C, leaving the site completely unmonitored for hours.

- Solution: After consulting with our engineering team, they deployed a network of six SDL500 4G solar security cameras. We provisioned them with oversized solar panels to maximize charging during short winter days and ensured the low-temperature BMS settings were optimized for the local climate. The 4G connectivity meant they didn’t need to worry about on-site Wi-Fi.

- Result: The SDL500 cameras maintained **100% operational uptime** through the entire winter, including a two-week period where temperatures never rose above -25°C. The contractor reported a **95% reduction in theft-related losses** and was able to use the high-definition footage to successfully prosecute two individuals for trespassing. The project manager stated, “These cameras paid for themselves in the first month. We no longer waste time and money dealing with failed cameras.”

Why B2B Partners Choose UBOXCAM for Cold-Climate Markets

For our partners—be they distributors, brand owners, or professional installers—the SDL500 is more than a product; it’s a business tool. It’s about building a brand that customers can trust when conditions are at their worst.

For Distributors & Wholesalers: Offering the SDL500 means providing a product that drastically reduces winter-related RMAs and support tickets. You can confidently market a premium solution for cold climates, setting yourself apart from competitors selling unreliable, fair-weather cameras.

For Installers & Integrators: Every truck roll to a remote site to replace a frozen camera costs you time and profit, especially in hazardous winter conditions. Installing the SDL500 means you do the job once and do it right. This enhances your reputation for quality and leads to more referrals.

For Brand Owners & 4G Operators: Through our ODM/OEM program, we can customize the SDL500 to carry your brand. This allows you to launch a top-tier, cold-weather-rated 4G solar camera into the market quickly, backed by our proven engineering and manufacturing expertise.

Don’t let your customers be another statistic of winter camera failure. Contact our B2B solutions team to discuss wholesale pricing and customization options for the SDL500.

Your Checklist for a True Winter-Proof Security Camera

When selecting a camera for a cold climate, don’t be swayed by marketing buzzwords. Use this engineer-approved checklist to vet your options:

- Verified Operating Temperature: Demand a certified operating range that goes down to at least -20°C, with -30°C being the gold standard for Canadian winters.

- Battery Chemistry: Confirm the camera uses high-quality, low-temperature Lithium Iron Phosphate (LiFePO4) batteries, not standard Li-ion.

- Advanced BMS Features: Ask specifically if the BMS includes low-temperature charging cutoff and a pre-heating circuit. If the supplier can’t answer, it’s a major red flag.

- Housing and Seal Materials: Inquire about the specific materials used. Look for polycarbonate or metal alloy housings and silicone seals.

- Real-World Proof: Request case studies or deployment references from similar climates. A truly reliable product will have a track record to prove it.

Choosing a security camera for a market like Canada isn’t about finding the cheapest option. It’s about investing in engineering that delivers unwavering reliability. A camera that works only nine months a year is a failed investment. The SDL500 is designed and built to provide true, 365-day security, ensuring peace of mind no matter how low the thermometer drops.

Protect your assets, your reputation, and your bottom line this winter. Explore the technical specifications of our SDL500 long-range wireless camera or reach out to our team for a personalized quote for your next project.