Solar Security Camera Factory: Ensuring Quality and Global Compliance with CE, FCC, RoHS

CE, FCC, RoHS Certifications: How UBOXCAM Ensures Product Quality and International Compliance

For any business in the security hardware space—be it a brand, a distributor, or an Amazon seller—navigating the maze of international regulations is a critical challenge. Sourcing a product that fails to meet CE, FCC, or RoHS standards isn’t just a minor hiccup. It can lead to seized shipments, hefty fines, and irreparable damage to your brand’s reputation. This is the single biggest non-commercial risk you face.

As an engineering-led factory with over a decade of experience, we don’t treat compliance as a final checkbox. We build it into the DNA of our products from the very first circuit diagram. Understanding these certifications is crucial for your business, as they are your passport to global markets and a guarantee of product quality.

What Are CE, FCC, and RoHS? An Engineer’s Breakdown

These acronyms are more than just logos on a box; they represent a rigorous commitment to safety, performance, and environmental responsibility. For B2B clients, they are a non-negotiable mark of a professional and reliable manufacturing partner. Let’s break down what they mean for a solar security camera.

- CE (Conformité Européenne): This is your key to the European Economic Area (EEA). It declares that a product meets the EU’s high safety, health, and environmental protection requirements. For a wireless camera, this primarily involves the Radio Equipment Directive (RED), ensuring it operates safely without interfering with other radio spectrum users, and the Low Voltage Directive (LVD) for safety.

- FCC (Federal Communications Commission): This is a mandatory certification for all electronic products that are manufactured or sold in the United States. It certifies that the electromagnetic interference from a device is under limits approved by the FCC. For 4G and WiFi cameras, this is paramount to guarantee stable connectivity and prevent product recalls.

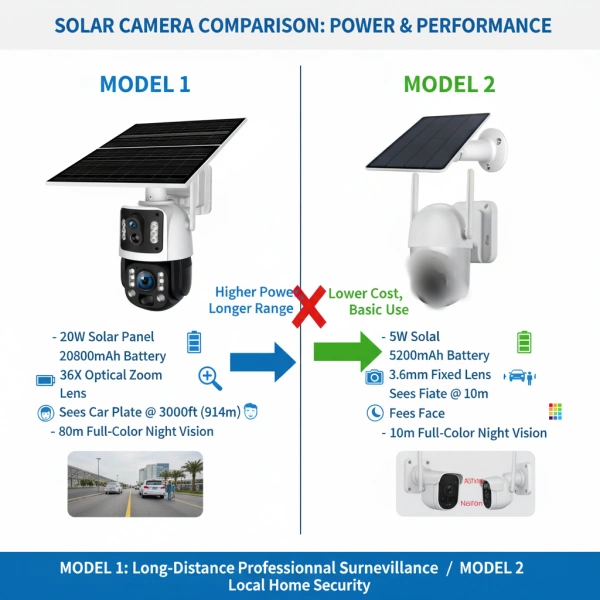

- RoHS (Restriction of Hazardous Substances): Originally an EU directive, RoHS is now a global standard. It restricts the use of ten specific hazardous materials in the manufacture of various types of electronic and electrical equipment, including lead, mercury, and cadmium. This not only demonstrates environmental responsibility but also enhances product reliability, as compliant manufacturing often demands higher-quality processes. [SVG_Comparison_Chart_1]

The UBOXCAM Certification Process: A Commitment to Excellence

Many suppliers view certification as a bureaucratic hurdle to be cleared at the end. We see it as a guiding philosophy throughout our entire design and production workflow. This proactive approach de-risks your investment and ensures a smoother path to market.

Our process is built on a foundation of engineering discipline, which we call “Design for Compliance.” [SVG_Flowchart_2]

- Phase 1: Design & Component Selection: Compliance begins at the R&D stage. Our engineers meticulously select core components like 4G modules and WiFi chipsets that are already pre-certified. We design our PCB layouts to minimize electromagnetic radiation from the start, and our bill of materials (BOM) strictly adheres to RoHS-compliant materials.

- Phase 2: In-House Pre-testing: Before a single unit is sent to an external lab, it undergoes rigorous pre-testing in our own facility. Using spectrum analyzers and EMI chambers, we test for radio frequency emissions and susceptibility. This catches potential issues early, saving immense time and cost—a benefit we pass directly to our B2B partners.

- Phase 3: Third-Party Laboratory Validation: We partner with world-renowned testing laboratories like SGS, TÜV, and Intertek for official certification. Because of our thorough pre-testing, this stage becomes a validation rather than a discovery process, ensuring high pass rates and predictable timelines.

- Phase 4: Continuous Production Quality Control: Certification is not a one-time event. Our quality assurance team implements strict controls on the production line, including incoming material inspection and regular batch testing, to guarantee that every camera rolling off our line meets the same standard as the one certified by the lab.

How Compliance Translates to Your Business Success

Choosing a compliant manufacturer like UBOXCAM directly impacts your bottom line. It’s the difference between building a sustainable global brand and facing constant operational fires. The technical standards we adhere to provide tangible commercial advantages for our partners.

Here’s a clear comparison of the business outcomes:

| Business Aspect | With UBOXCAM (Certified Products) | With Non-Certified Suppliers |

|---|---|---|

| Market Access | Unrestricted legal access to US, EU, and other major markets. | Blocked from key markets; risk of being delisted from platforms like Amazon. |

| Customs Clearance | Smooth and predictable. Full, verifiable documentation provided. | High risk of shipment seizure, delays, and costly inspections. |

| Brand Reputation | Builds trust with end-users and channel partners. Seen as a high-quality, reliable brand. | Damaged by product recalls, poor reviews, and legal challenges. |

| Product Reliability | Lower failure rates due to superior components and manufacturing (e.g., RoHS). | Higher return rates from interference issues and component failure. |

| Legal & Financial Risk | Minimized. Protected from compliance-related fines and lawsuits. | High exposure to fines, litigation, and inventory write-offs. |

By ensuring every product meets international standards, we empower our B2B clients—from startups to established distributors—to focus on marketing and sales, confident that the hardware foundation is solid.

Case Study: Launching a 4G Solar Camera Brand in Germany

- Problem: A German brand partner aimed to introduce a new line of custom 4G solar security cameras for construction sites. They were highly concerned about the complex CE RED and RoHS requirements, which had caused significant delays with a previous supplier.

- Solution: UBOXCAM’s engineering team was involved from the initial concept. We co-designed the product, ensuring all components and materials were RoHS compliant from the start. We provided a complete CE Technical File, including comprehensive EMC and RF pre-test reports, which massively accelerated the formal certification process with TÜV.

- Result: The client achieved full CE certification 30% faster than their projected timeline, allowing them to launch before their peak selling season. They successfully secured a major contract with a national building supplier, who cited the robust compliance documentation as a key factor in their decision. The product’s field failure rate due to electronic issues remains below 0.1%.

Common Compliance Pitfalls and How to Avoid Them (Q&A)

Navigating compliance can be tricky. Here are answers to common questions we receive from B2B clients, based on over a decade of experience.

- Q1: If I use a CE-certified 4G module, is my entire camera CE-certified?

- A: No. This is a critical and expensive mistake. While using a certified module is a vital first step, the final product must be tested as a complete system. The camera’s own electronics, casing, and power supply can all create interference. The CE RED certification applies to the final product, not just its parts. We manage this holistic testing process for you.

- Q2: My shipment was held by customs. The supplier gave me a certificate. What happened?

- A: This often stems from mismatched or invalid documentation. A supplier might provide a certificate for a different model, an expired certificate, or one from a non-accredited lab. At UBOXCAM, every shipment is backed by a full, traceable documentation package that precisely matches the goods, ensuring smooth customs clearance.

- Q3: How does RoHS compliance affect the reliability of an outdoor security camera?

- A: Beyond environmental benefits, RoHS has a direct impact on durability. For example, lead-free solder (a RoHS requirement) has a different melting point and requires more precise process control during manufacturing. As a factory specializing in this, our refined soldering process results in stronger, more reliable circuit board connections that better withstand the vibration and temperature swings experienced by an outdoor camera.

Your Compliance Checklist for Sourcing Solar Security Cameras

To protect your business, use this checklist when evaluating any potential manufacturing partner:

- ✅ Demand Full Test Reports: Don’t settle for just the certificate. Ask for the complete CE (EMC, LVD, RED), FCC, and RoHS test reports. A professional supplier will have these readily available.

- ✅ Verify Certificate Authenticity: Check the certificate number against the issuing laboratory’s public database. This confirms it is legitimate and current.

- ✅ Confirm Model Number Match: Scrutinize the documents to ensure the certificate applies to the exact product model you are purchasing, not a “similar” one.

- ✅ Inquire About In-House QA: Ask how they ensure ongoing compliance. Do they perform batch testing? What are their incoming quality control (IQC) procedures for materials?

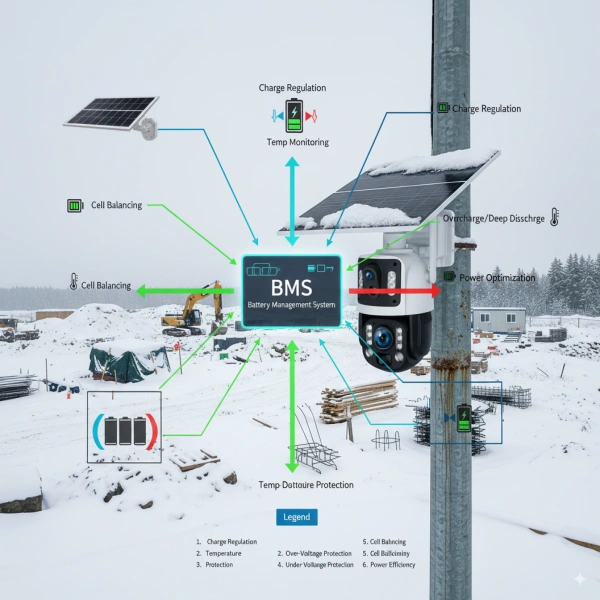

- ✅ Discuss Future-Proofing: Does the supplier have a plan for emerging regulations, such as the EU’s Cyber Resilience Act? A forward-thinking partner like UBOXCAM is already integrating these future requirements into our BMS and firmware design.

Ultimately, certification is not an expense; it’s a fundamental investment in your brand’s future. It unlocks markets, builds customer trust, and safeguards you from crippling legal and financial risks. By partnering with an engineering-first manufacturer like UBOXCAM, you are not just buying a camera; you are securing a compliant, reliable, and competitive product pipeline.

Ready to expand your business with globally certified hardware? Contact our engineering team today to discuss your custom project and discover how our fully compliant wireless outdoor security cameras can accelerate your growth.