UN38.3 & MSDS: Your Guide to Compliant Solar Security Camera Shipping

Lithium Battery Transportation Reports: Your Key to Safe and Compliant Global Shipping

You’ve finalized the design for your new line of solar security cameras. Production is complete, and the units look perfect. But when it’s time to ship, your entire project grinds to a halt. Your cargo is flagged, delayed at customs, or even rejected by the carrier. The culprit? The small but powerful lithium battery inside each camera. For any business importing or distributing electronics, this is a costly and frustrating reality.

As an engineer with over a decade of experience designing and manufacturing these products, I’ve seen firsthand how overlooking battery transportation compliance can derail a business. The solution lies in two critical documents: the UN38.3 Test Report and the Material Safety Data Sheet (MSDS). Understanding these isn’t just a matter of ticking boxes; it’s fundamental to ensuring safety, avoiding legal penalties, and maintaining a seamless global supply chain.

This article will demystify the complex world of lithium battery shipping regulations. We will break down what these reports are, why they are non-negotiable, and how a proficient manufacturing partner like UBOXCAM manages this process to protect your business interests.

Why Lithium Batteries Are Classified as Dangerous Goods

First, it’s crucial to understand why regulators are so stringent. Lithium-ion and lithium-polymer batteries, the powerhouses behind modern wireless devices like solar security cameras, have an extremely high energy density. While this is great for performance, it also carries inherent risks if the batteries are poorly manufactured, damaged, or exposed to extreme conditions.

The primary concern is “thermal runaway,” a chain reaction where a rise in internal temperature can cause the battery to vent flammable gases, catch fire, or even explode. Incidents on cargo planes have led global bodies like the United Nations (UN) and the International Air Transport Association (IATA) to classify lithium batteries as Class 9 Dangerous Goods. This classification doesn’t mean they can’t be shipped; it means they must be proven safe and handled according to strict protocols.

Unpacking the Essential Documents: UN38.3 vs. MSDS

To legally transport lithium batteries, manufacturers must provide proof of their safety and stability. This proof comes in the form of specific, standardized documentation. The two most important are the UN38.3 report and the MSDS.

The UN38.3 Test Report is the gold standard for battery transport safety. It’s not just a piece of paper; it’s the summary of a series of grueling physical and environmental tests performed by an accredited third-party laboratory. These tests simulate harsh transport conditions:

- T1 – Altitude Simulation: Simulates unpressurized air transport.

- T2 – Thermal Test: Subjects the battery to extreme temperature cycles.

- T3 – Vibration: Mimics vibrations during transport.

- T4 – Shock: Assesses physical durability against impacts.

- T5 – External Short Circuit: Tests the battery’s response to an external short.

- T6 – Impact/Crush: Simulates mechanical abuse.

- T8 – Forced Discharge: Ensures stability under forced discharge conditions.

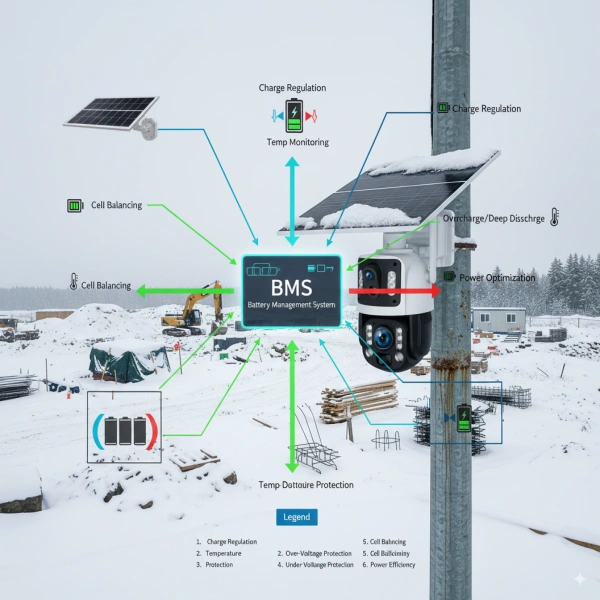

A passing UN38.3 report is concrete evidence that the battery’s design, including its integrated Battery Management System (BMS), is robust enough to be transported safely. Without it, your products will not be allowed on an aircraft. Learn more about how a BMS is the key technology that protects the battery.

The Material Safety Data Sheet (MSDS), sometimes called a Safety Data Sheet (SDS), serves a different but complementary purpose. It is a detailed document outlining the chemical properties of the battery, potential hazards, safe handling procedures, and emergency response measures. While UN38.3 proves the battery’s physical resilience, the MSDS informs everyone in the logistics chain—from warehouse staff to cargo handlers and emergency crews—how to manage the product safely.

Here is a clear comparison of these two essential documents:

| Feature | UN38.3 Test Report | MSDS (Material Safety Data Sheet) |

|---|---|---|

| Purpose | Certifies the battery is safe for transport after rigorous testing. | Provides comprehensive hazard, handling, and emergency information. |

| Basis | Results from a series of 8 specific physical and environmental tests. | Based on the battery’s chemical composition and inherent properties. |

| Requirement | Mandatory for air, sea, and land freight of lithium batteries. | Required by carriers, freight forwarders, and for customs clearance. |

| Audience | Regulators, Airlines, Shipping Companies. | Logistics Staff, Handlers, Emergency Responders, Customs Officials. |

Our Manufacturing Process: Building Compliance from the Ground Up

At UBOXCAM, compliance is not an afterthought; it’s engineered into our products from day one. Our process ensures every battery-powered security camera we ship is fully compliant and ready for global distribution.

First, we source our lithium-ion cells exclusively from top-tier suppliers who already provide cell-level UN38.3 certification. Next, our engineers design the complete battery pack, integrating a sophisticated BMS to manage charging, discharging, and temperature for optimal safety and longevity. This entire custom pack then undergoes its own UN38.3 testing at an accredited lab to certify it as a complete unit.

Once certified, we compile the full documentation package: the final UN38.3 report, an up-to-date MSDS, and the “Identification and Classification Report for Transport of Goods.” This final report classifies the shipment according to IATA regulations—for example, as UN3481 (Lithium-ion batteries contained in equipment)—and specifies the exact packing instructions (e.g., PI967). This meticulous approach ensures that when you place an order with us, the logistics are already handled.

Case Study: Navigating a Complex Shipment to the EU

Problem: A brand partner in Germany urgently needed an air shipment of 500 dual-lens solar security cameras for a large-scale construction project. The project deadline was unforgiving, and any customs delay would result in significant financial penalties for our partner.

Solution: Because our compliance process is standardized, our logistics team was able to act immediately. We provided the freight forwarder with the complete, up-to-date documentation package: the UN38.3 report for the specific battery model, a compliant MSDS, and the correct classification report identifying the shipment as UN3481. We also ensured the outer cartons were marked with the required Class 9 hazard labels and handling instructions.

Result: The shipment cleared German customs without a single query, arriving two days ahead of schedule. Our partner fulfilled their contract on time, strengthening their reputation for reliability. By having the correct documentation ready, we prevented potential delays that could have cost them over €10,000 in penalties and damaged their relationship with their end client.

Common Pitfalls and How to Avoid Them

Navigating battery shipping can be tricky. Here are some common questions and issues we help our clients avoid:

- Can I use an old UN38.3 report? Regulations, especially the IATA Dangerous Goods Regulations (DGR), are updated annually. A report that was valid last year may not be compliant today. We ensure our documentation aligns with the latest version of the regulations.

- My freight forwarder will handle it, right? While a good forwarder is essential, they can only work with the documentation you provide. The legal responsibility for correct classification and documentation lies with the shipper (the manufacturer). A proactive partner like UBOXCAM removes this burden from you.

- What is the difference between shipping spare batteries and batteries in cameras? The classification and packing instructions are different. Batteries shipped alone (UN3480) face much stricter rules than batteries shipped inside a device (UN3481). We manage this distinction flawlessly based on your order, whether it’s for complete wireless outdoor security cameras or spare parts.

A B2B Buyer’s Checklist for Battery Compliance

When vetting a potential manufacturing partner, use this checklist to gauge their expertise in battery compliance. Their answers will reveal their level of professionalism and attention to detail.

- Does the supplier proactively provide a current UN38.3 test report for the specific battery model in your product?

- Can they supply a detailed and accurate MSDS that matches the battery’s specifications?

- Is their logistics team knowledgeable about the latest IATA DGR and how to classify different types of shipments?

- Do they have a proven track record of shipping to your target markets (e.g., North America, Europe) and understanding regional nuances?

- Do they use certified packaging and proper labeling for dangerous goods shipments?

Compliance Isn’t an Obstacle, It’s Your Competitive Advantage

In the global marketplace, speed and reliability are paramount. Lithium battery compliance is not a bureaucratic hurdle; it is a critical component of a resilient and professional supply chain. Getting it right prevents costly delays, avoids legal trouble, ensures the safety of handlers, and protects your brand’s reputation.

Partnering with a manufacturer that has deeply integrated these compliance protocols into its operations is a strategic advantage. It transforms a potential liability into a non-issue, allowing you to focus on what you do best: growing your business. Don’t let logistical complexities dictate your success. **Contact UBOXCAM today** to learn how our fully compliant solar security camera solutions can provide a seamless path from our factory to your market.